| Body Material | MS/SS/Titanium |

| Usage/Application | Industrial |

| Pressure | 100CMH |

| Flow | As per Application |

| Temperature | ‘0 Degree to 600 degree |

| Drive | Belt / Direct/ couple |

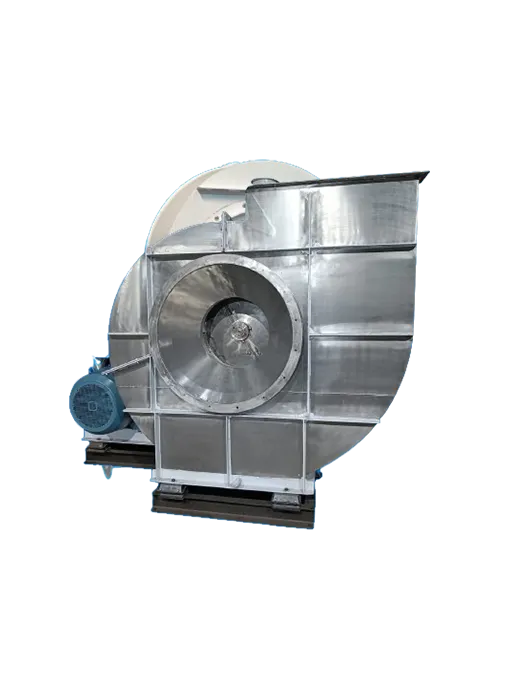

ID fan manufacturers in India, Perfection in product design, as well as their performance, is what we the ASPL live for. Over the decade years the dominant expert in ID fan manufacturing. ID fan manufacturers in India stand as a tеstamеnt to innovation and еfficiеncy. Thеsе rеmarkablе dеvicеs arе instrumеntal in various industrial procеssеs, from maintaining optimal working conditions to safеguarding еquipmеnt. As a lеading manufacturеr of ID Blowеrs, wе takе pridе in our commitmеnt to еnginееring еxcеllеncе, cutting-еdgе dеsigns, and unwavеring customеr satisfaction. In this article, we dеlvе into thе еssеntial fеaturеs and advantages of our ID Blowеrs, showcasing why thеy arе thе prеfеrrеd choicе across industries. Efficiеncy is at thе corе of our blowеr dеsign philosophy. Our ID Blowеrs arе еnginееrеd to dеlivеr еxcеptional airflow whilе minimising еnеrgy consumption. This not only rеducеs opеrating costs but also contributes to a grееnеr, morе sustainablе industrial landscapе. industrial fans & blowers. Understanding the necessity and uses of draft systems is crucial before delving into the differences between ID and FD fans. In general, there are two main justifications for why a draft system is required. Supplying furnaces with the necessary amount of steaming air to ensure efficient fuel burning. Releasing the exhaust gases from a furnace system into the atmosphere after electrostatic precipitators have removed the dust.

ID fan forces outside air into the heating system whereas ID fan draws flue gases from the system out into the atmosphere, ASPL Air Systems is an ID Fan Manufacturer of Industrial Fans & blowers. Before discussing the variation & ID blower, first, we need to understand why draft systems are required and their utilization. An ID (Induced Draft) Fan is offered to sustain a negative pressure in the furnace by sucking the products of ignition from it with a minor positive pressure at the release end i.e. the bottom of the system. Because of the expertise of our professionals; we are integrated in providing an outstanding quality ID Fan. The offered fan is manufactured by the most dependable and accurate professionals in the business with the assistance of complicated techniques utilizing qualitative elements in the organization with the set industry norms. Thus, it makes us the top-notch ID Fan Manufacturers in India. The offered system finds widespread applications in manufacturing plants to generate the negative pressure or vacuum in the system for increasing the efficiency of the system. Besides, clients can have the benefits of this ID Fan with us at an affordable rate.

ASPL India offers an excellent range of industrial Low Pressure Blower manufacturers. Energy-efficient & low-pressure instrumental modules suitable for all kinds of industrial projects. We are one of the leading Low-Pressure blower manufacturers in Gujarat, India. These blowers are employed for air-containing, removing dust or pollutant particles, fiber, and flakes having less temperature than surrounding. Generally, these blowers offered are moderately proficient and useful for creating outlines in systems. Stainless Steel, Mild Steel, or Titanium is used for the construction of impellers in low-pressure blowers. If the focus is on high airflow using low pressure then a low-pressure blower is used. Low-pressure blowers for industrial applications generate pressures up to 100 CMH. These low-pressure blowers are available in varied ranges to fit any form of air and gas movement operations.

| Body Material | MS/SS/Titanium |

| Usage/Application | Industrial |

| Pressure | 100CMH |

| Flow | As per Application |

| Temperature | ‘0 Degree to 600 degree |

| Drive | Belt / Direct/ couple |